20 Years Of Experience

Hongfa Shunda offer hundreds of standardized plastic enclosures across categories—delivering fast, cost-efficient solutions with no lengthy development cycles.

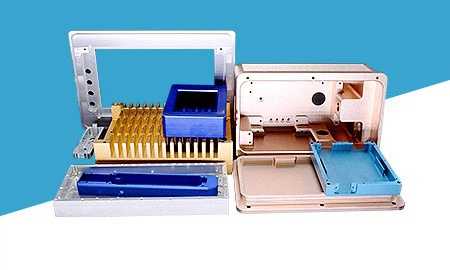

Our core strength: full plastic enclosure customization—including precision hole cutting, custom logo printing, tailored colors, and material options (ABS, PC, PA...)—plus end-to-end OEM/ODM support covering original design and mold development.

- Share your 2D/3D drawings or specs for a detailed quotation.

- Request our free plastic enclosure catalog today!

Premium Metal Enclosures for Streamlined Product Development

Shenzhen Hongfashunda Mould Co., Ltd, founded in 2007, is an all-round enterprise integrating research, design, production, and marketing. The company has a factory of over 5000 Sq.m and more than 120 employees. There are several departments, including R&D Dept, Tooling Dept, Hardware Dept, Plastic Dept, and Marketing Dept.

- Quality Management System ISO 9001, CE

- High-tech enterprises, SGS certificate

- PATENT: sand filter, self cleaning filter

Vast In-Stock Selection & Deep Customization: Meet Diverse Needs

-

Collaborative Design & Mold DevelopmentProvide a concept or drawing, and our engineering team will optimize the design and manufacture high-precision molds quickly, shortening your product time-to-market.

-

Multi-Material Enclosure CustomizationPlastic enclosures: Crafted from ABS, PC, PP engineering plastics—lightweight, high-insulation, cost-efficient for diverse applications.

Aluminum enclosures: High-strength, lightweight alloy with superior heat dissipation; precision CNC-machined and surface-treated for high-end instruments and communication gear.

Sheet metal enclosures: Cold-rolled steel/stainless steel built via laser cutting, bending, welding—sturdy for heavy-duty industrial control and power supply equipment. -

Comprehensive Secondary ProcessingOffer precision structural processing (hole opening, tapping, riveting, welding) and surface treatment (spraying, anodizing, silk-screen LOGO, custom packaging) to ensure the enclosure perfectly matches your product's functional and aesthetic positioning

One-Stop Integration: Hassle-Free & Efficient

All processes -- from design, mold making, production to surface treatment and packaging -- are completed in our own factories. We strictly control quality and delivery time, avoiding communication costs and quality risks from multi-party cooperation

Expert Technology & Reliable Quality

With nearly 20 years of technical experience, we have in-depth knowledge of plastic enclosure injection molding, aluminum enclosure stretching and anodizing, and sheet metal enclosure stamping and welding, ensuring every product meets industrial-grade quality standards

Flexible Production & Fast Response

We can flexibly adjust production lines for both small-batch trial production and large-scale orders, matching your R&D pace and market plans with rapid prototyping and stable supply

Cost Optimization & Value Enhancement

Through reasonable material selection, mold design optimization, and large-scale production, we help you control costs effectively while ensuring quality, enhancing your product's market competitiveness

How to work with us

Start Your Journey, Experience the Allure of HONGFA

-

Upload your 3D drawings and requirements to quickly obtain a quotation

-

Use our design service. Our experts can help you convert sketches or requirements into achievable drawings

-

Get drawing from Hongfa

WANT TO WORK WITH US?

Custom High-Quality Electronic Enclosures

Save Time, Build a Unique Enclosure That Perfectly Matches Your Product, Help You Capture Market Share Fast & Earn Rave Reviews

What Client Say

Latest news and events

-

![Guide To Selecting Materials For Electronic Plastic Enclosures]() Dec 13, 2025Guide To Selecting Materials For Electronic Plastic EnclosuresIn electronic product design, the choice of enclosure materials directly impacts the product's durability, safety, and cost control. Electronic plastic enclo...view more

Dec 13, 2025Guide To Selecting Materials For Electronic Plastic EnclosuresIn electronic product design, the choice of enclosure materials directly impacts the product's durability, safety, and cost control. Electronic plastic enclo...view more -

![Classification Of Metal Molds By Forming Process - Essential Tools For Modern Manufacturing]() Dec 10, 2025Classification Of Metal Molds By Forming Process - Essential Tools For Modern ManufacturingMetal molds, also known as dies or tools, are critical components in modern manufacturing, enabling the mass production of precise metal parts across indust...view more

Dec 10, 2025Classification Of Metal Molds By Forming Process - Essential Tools For Modern ManufacturingMetal molds, also known as dies or tools, are critical components in modern manufacturing, enabling the mass production of precise metal parts across indust...view more -

![Comparison Of Signal Shielding Performance Between Galvanized Plate, Steel Plate, And Aluminum Plate]() Nov 18, 2025Comparison Of Signal Shielding Performance Between Galvanized Plate, Steel Plate, And Aluminum PlateThis overview compares galvanized, steel, and aluminum plates for electronic enclosure signal shielding (against EMI/RFI). Steel excels at low-frequency magn...view more

Nov 18, 2025Comparison Of Signal Shielding Performance Between Galvanized Plate, Steel Plate, And Aluminum PlateThis overview compares galvanized, steel, and aluminum plates for electronic enclosure signal shielding (against EMI/RFI). Steel excels at low-frequency magn...view more